Lightweight encapsulation of electronics

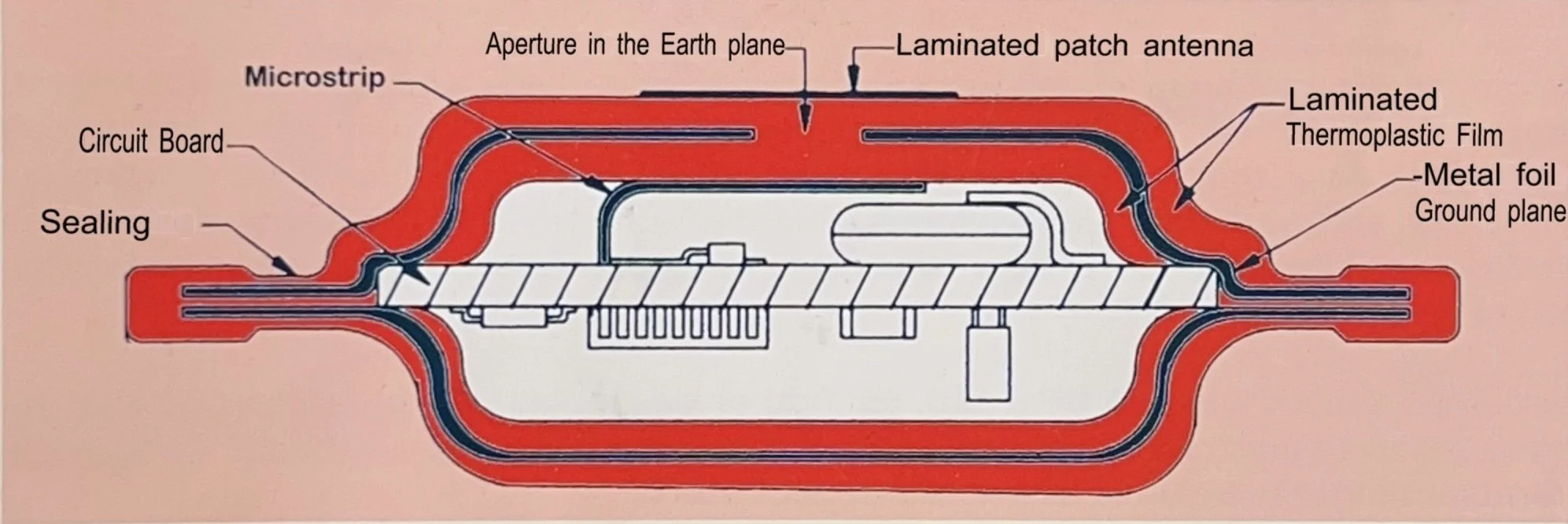

PROOFCAP is made of a laminate which is drawn into a bowl shape with a sealing edge. The edge can be melt welded to another part to form an encapsulation, which include the circuit. The capsule is safe for diffused water and electric shielded. The very special laminate is manufactured in a flat shape of metal foil and thermoplastic films, with a special treatment that provides the very good adhesion. The metal is selected with the intension of being recycled and to contribute to good electrical conductivity.

In a special case laminate with a surface of stainless steel, can be used.

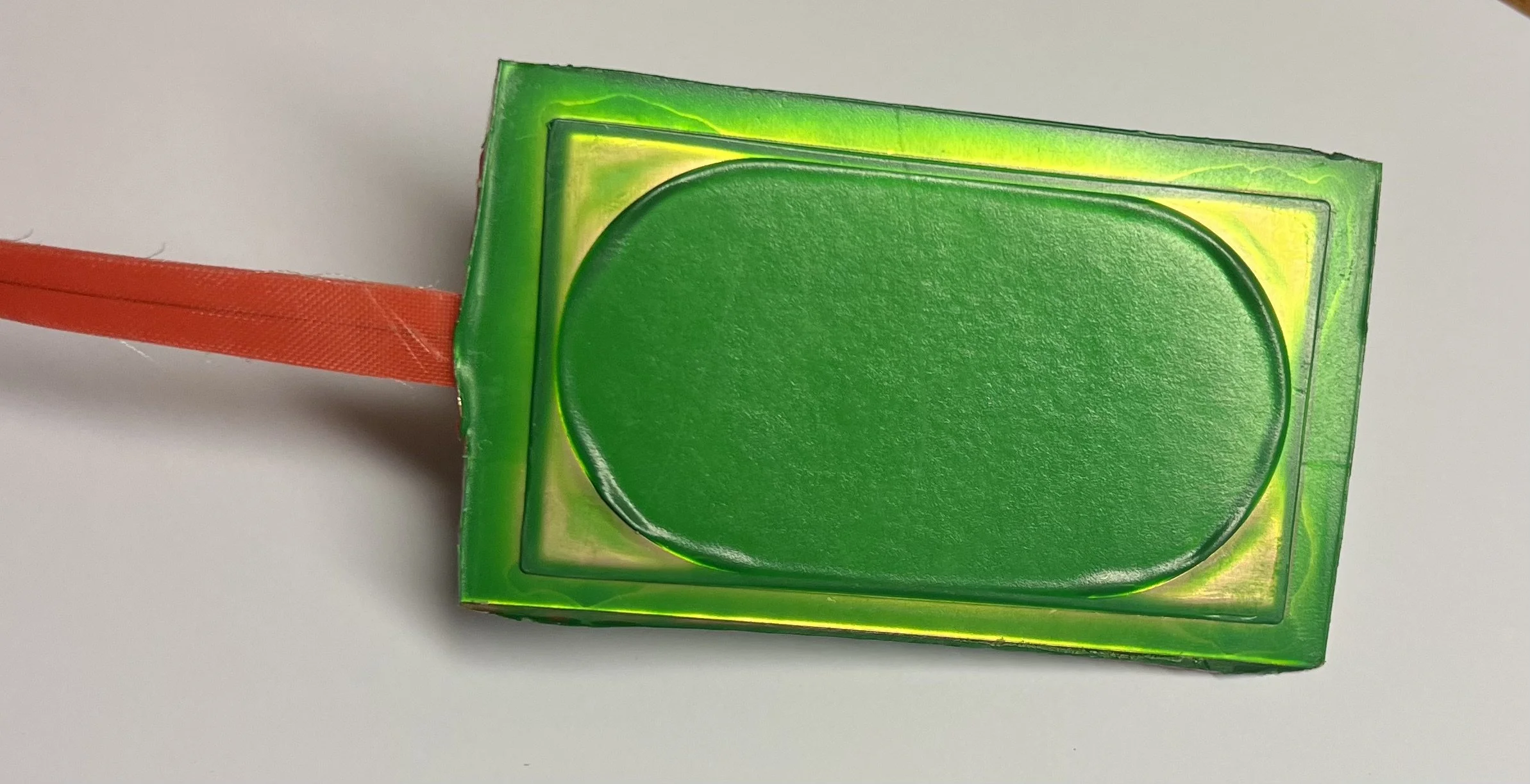

Shielding is assured by rows of dots compressions from the patented sealing tool, which short circuits the groundings along the sealing in the circuit and the metal in the laminate. The thermoplastic films binds the laminates together and includes the grounding dots so that they cannot oxidize and lose contact. The PROOFCAP laminate thickness is 0,5 mm. The whole outer surface of the capsule is smooth and protected from corrosion, by the plastic film. Outside the film can be coloured and the laminate can have the brand preset in relief.

PROOFCAP laminate can be combined with a thicker bottom metal plate necessary for fixation and cooling. The adhesion strength can be used to integrate mechanical items such as cooler, front and fixing items without the use of screws. Soldering pads, electrical conductors and antenna patterns can be applied directly onto the PROOFCAP laminate. This opens up for small, integrated and low weight products. The laminate is then formed into a shell that can be melt-sealed around the circuit board at the electronics manufacturer to form a hermetic capsule.

PROOFCAP supplies customer-shaped shells and tools for sealing at the electronics manufacturer. The shells can be equipped with flat cable feedthrough, heat sink, microstrip fed patch antenna. The circuit is protected against moisture and electric interference. Radio communication can take place directly from the capsule surface. The influence of the HF field on the circuit function can be easily tested before the capsule is sealed.

PROOFCAP shielding saves weight compared to casted aluminium boxes and pottings in epoxies or polyurethane. A 100x100mm cover weighs typically 20 grams.

PROOFCAP also consults in design and prototypes

PROOFCAP was originally developed together with leading telecommunication companies and crucial further development has taken place.